Advantages of Wet Blasting Machines

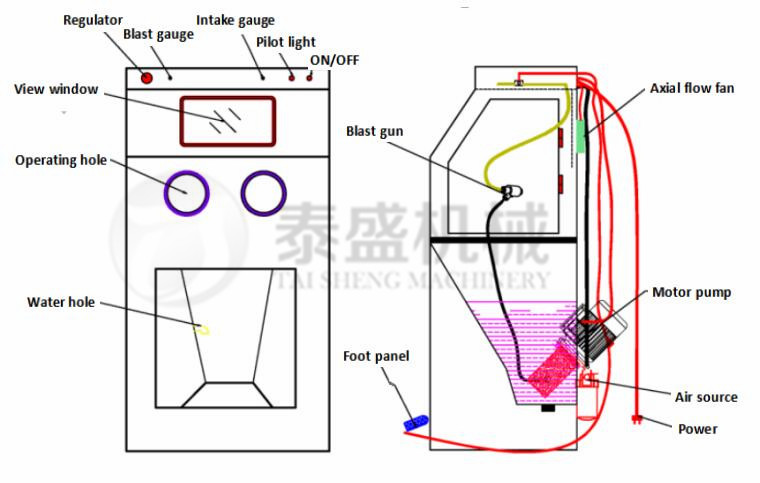

Wet blasting machines have revolutionized surface preparation and cleaning processes across various industries. A wet blasting machine, also known as a slurry blasting machine, utilizes a mixture of abrasive media, water, and compressed air to efficiently clean, degrease, or prepare surfaces for a wide range of applications. so what is the advantages of wet blasting machines and discuss their key characteristics, primary applications, and important considerations when purchasing one.

Wet blasting machines offer an unparalleled level of precision and control when compared to traditional dry blasting methods. By adjusting parameters such as air pressure, abrasive media, and water flow rate, operators can fine-tune the process to achieve the desired surface finish. This level of control makes wet blasting machines ideal for intricate and delicate workpieces, where precision is paramount.

Reduced Dust Emission

Unlike dry blasting, which generates a significant amount of airborne dust and debris, wet blasting machines effectively suppress dust emissions. The addition of water to the abrasive media captures particles at the source, preventing them from becoming airborne. This not only ensures a safer working environment but also reduces the need for elaborate dust containment measures.

Minimal Material Waste

Wet blasting minimizes material waste by recycling the abrasive media. The water suspends the particles during the blasting process, allowing them to be reused multiple times. This not only reduces the overall cost of abrasive media but also contributes to a more sustainable and eco-friendly blasting process.

Gentle on Substrates

Wet blasting is gentle on the underlying substrate, making it suitable for a wide range of materials, including metals, plastics, composites, and even fragile surfaces like glass. The combination of water and abrasive media removes contaminants without causing damage, warping, or deformation to the substrate.

Versatility in Abrasive Selection

Wet blasting machines accommodate various types and sizes of abrasive media, allowing operators to choose the most suitable material for the task at hand. This versatility ensures optimal results for different applications, from rust removal to surface texturing.

Improved Surface Cleaning

The use of water in wet blasting enhances the cleaning capabilities of the process. It effectively removes grease, oil, contaminants, and residues from surfaces, leaving them thoroughly cleaned and prepared for subsequent treatments or coatings.

In conclusion, wet blasting machines offer a multitude of advantages, including precision, reduced dust emission, minimal material waste, gentle treatment of substrates, versatility in abrasive selection, and improved surface cleaning. These advantages make wet blasting machines indispensable in a wide range of industries, from automotive and aerospace to marine and electronics manufacturing.

When purchasing a wet blasting machine, carefully consider factors such as machine type and size, abrasive media compatibility, water recycling capabilities, and control options. Making the right choice will not only ensure optimal performance but also contribute to cost savings and a more sustainable blasting process.

For all your wet blasting machine needs, do not hesitate to contact us. Our experts are ready to assist you in selecting the perfect machine to meet your specific requirements, ensuring efficient and effective surface preparation and cleaning for your applications.